Electric Motorbike

Custom PID Controller | Suspension CAD | Injection Molded Part Design | EV Charger Design | Suspension Modeling and Analysis | Custom Vinyl Wrap

Monday Motorbikes

I wore many hats as an engineering intern for Monday Motorbikes. Projects featured below include elements of Mechanical Design, Control Systems, Manufacturing, Product Design, Styling, Brand Strategy, and Business Intelligence.

Custom PID Controller

Due to electric bicycle regulations, the 5.5kW motorbike needed an economy mode that was power-limited to 1000 Watts and 20 mph. The original team's solution had been to artificial choke the throttle (i.e. if mode = econ, throttle = 0.25*throttle). I worked with an electrical engineering intern to develop a custom PID controller in MATLAB using the Simulink package. This algorithm was then uploaded to the brains of the bike via an Arduino and allowed the motor controller to effectively limit power in economy mode. Data collected during road-testing confirmed a smooth transition between poles within 5% range of the 1000 Watt target.

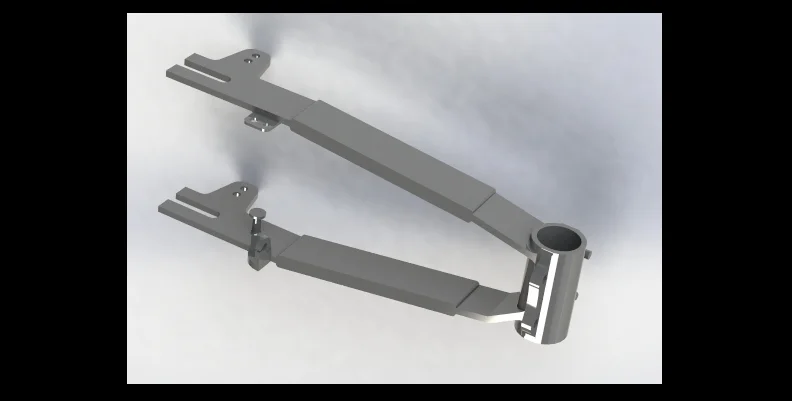

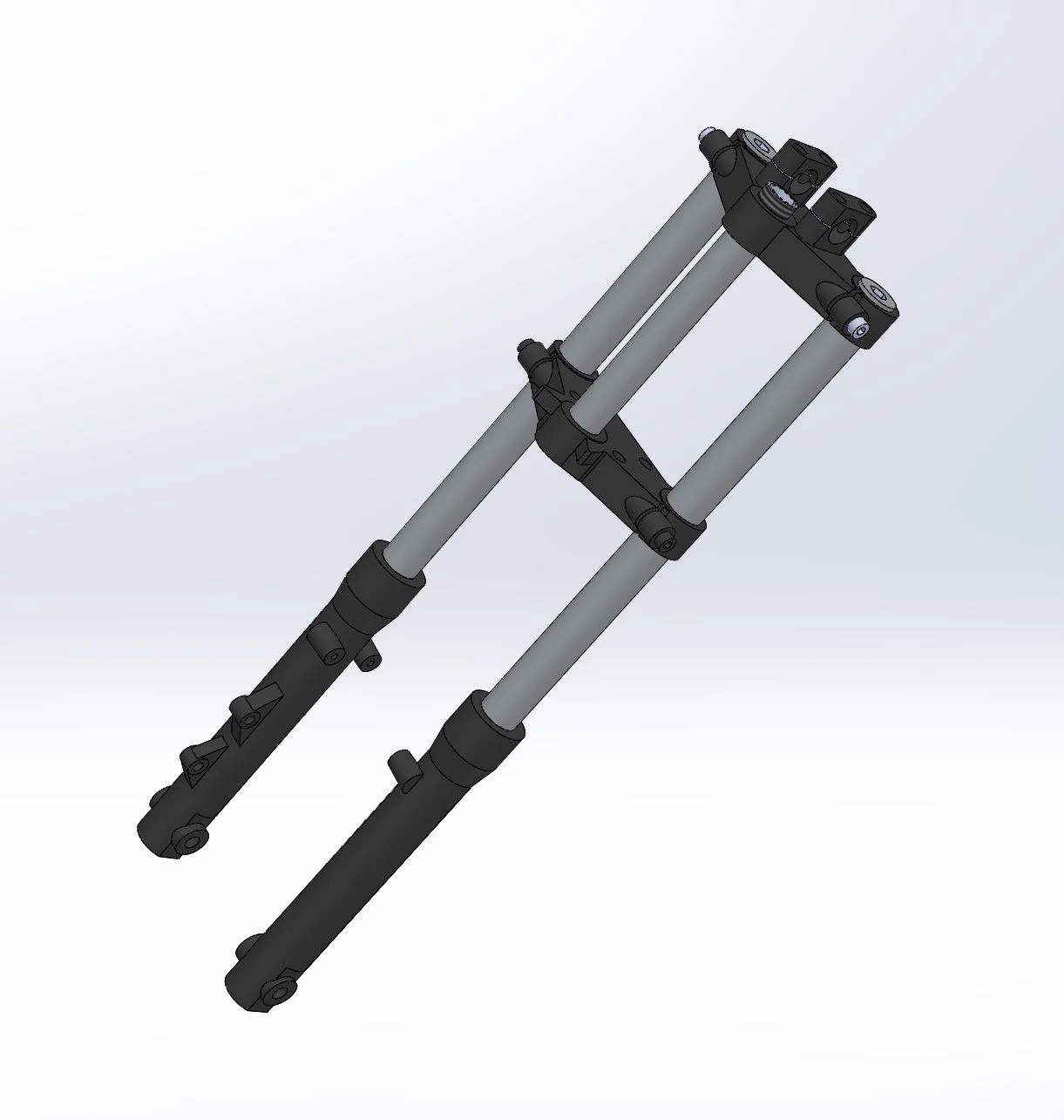

Suspension CAD

I produced these CAD models by reverse engineering an Italian-made front fork assembly and a rear swing arm part used on the M1. I took precise measurements of the physical model using calipers and micrometers and created a 3D assembly model in SolidWorks. The model was then added to the full bike assembly CAD.

The CAD models were then used to design and develop "Bike on a Board", a project partnership with Intel to develop the next generation chip for motorbike-to-cloud connectivity.

Chain Guard Restyling

I worked with the Director of Product Design Engineering to restyle the motorbikes chain guard. The redesign was an attempt to have the part injection molded by an external manufacturer rather than vacuum forming it in-house.

I developed these concept sketches to explore different forms and functions based on engineering specifications (e.g. mounting locations, durability, weight) and user specifications (e.g. prevent entanglement, keep riders back dry).

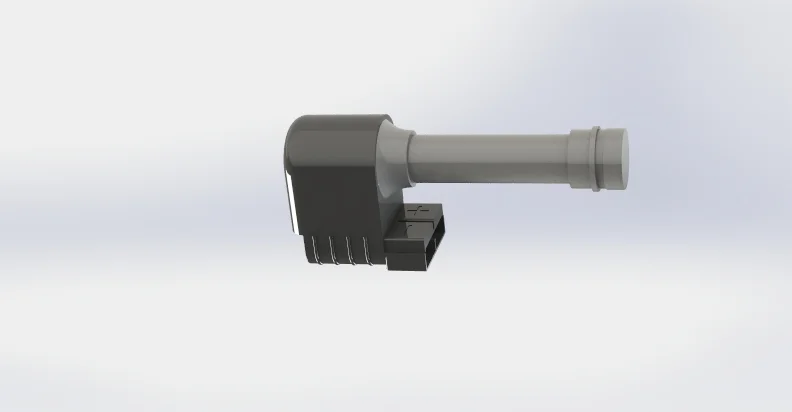

Off-Bike Charging System Design

Many of our customers lived in apartment buildings or townhomes, leaving them unable to charge their motorbikes. I was tasked with designing and prototyping an off-bike charger system.

Using the principles of design thinking, I began by conducting phone UX interviews to understand the needs and wants of our customers. These insights led me to a design charge: the desire for a lightweight, portable, sleek, easy-to-use charger and handle system.

I worked to create a number of concepts, ultimately closing on two for prototyping. The first proof of concept prototype was made out of wood and scrap plastic. I then added a four-bar latch mechanism (which I designed and machined), a smart charger, anderson connectors, etc. in subsequent iterations. Testing and design then proceeded using sketching, CAD, and rapid prototyping. I also designed and fabricated fool-proof electrical harnesses that allowed for the user to seamlessly connect independent batteries to the smart charger.

Additionally, I had the opportunity to collaborate with contract manufacturers in China as this project closely interfaced with the handle system being incorporated on DLG's new battery designs.

Suspension and Chassis Modeling

I sought to design and simulate a suspension system for the M1 electric motorbike that would allow it to conquer obstacles with the ease of a dirt bike while maintaining the smooth, refined ride of a road bike.

I simulated a mono-shock rear suspension design by creating a mathematical model in MATLAB based on the coupled equations of motion (bounce and pitch dynamics). I assumed a fixed front fork angle and pre-defined displacements taken from average road condition data (speed bumps, potholes, curbs, etc.). I then varied shock stiffnesses and rear shock angle to determine the optimal setup for the suspension.

This project involved translating a complex mechanical system into a free body diagram, using that FBD to develop a coupled three-mass model for vehicle dynamics, and then using MATLAB to simulate real-world disturbances on the system. I then used engineering analysis to assess stability, natural frequency, and bounce and pitch angle under simulated operating conditions. This engineering analysis was critically analyzed to make informed engineering recommendations for further redesign.

Custom Vinyl Wrap

"Fourth of July is tomorrow. I could wrap that bike in an American flag theme. It would probably only take about 2 to 3 hours", I said to the team...

15 hours later, there I was, taking a nap on the couch in the Monday Motorbikes Lab. I had spent all night cutting and laying these vinyl decals by hand and I had enjoyed every minute of it. The "Uncle Sam " bike was a pretty epic independence day ride for our crew...totally worth it!